-

Services

-

References

We are at home in the most diverse markets! An extract from our references.

-

Are you looking for an existing sensor solution?

Then you will certainly find what you are looking for in our SENSOTEC Portfolio.

-

-

References

-

Media Room

Our expertise in sound and vision: Find exciting content about us and our services.

-

You have the idea?

We have the competencies. The development portrait.

-

-

Company

-

In search of a new challenge?

All information about a career at STEINEL Solutions.

-

We train!

We accompany young people on their way into working life.

-

- Career

- Contact

Optimum learning effect thanks to exciting projects! Our apprentices pursue great projects on which they work independently and efficiently. We present them here.

Press lid

Jonas has developed a device to press a cover onto the corresponding housing. This solution is both functional and easy to use for assembly. This included creating all the production documents, ordering the parts, assembling and testing the finished device. The housing and cover can now be placed in the holder and pushed backwards. The cover is then pressed into place using a toggle press.

Automatic window control

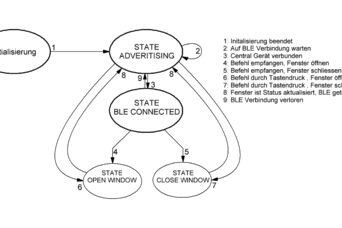

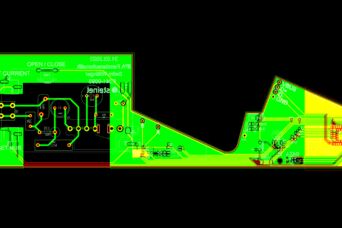

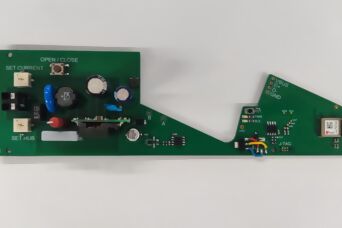

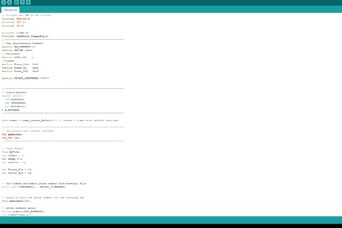

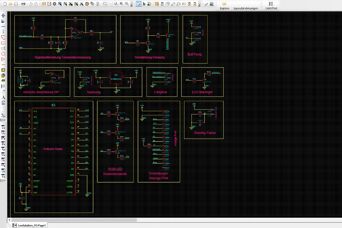

As part of his training as an electronics technician, Selim was given the «window automation» project for his individual practical work (IPA) to solve the problem of night-time cooling in rooms with open tilt windows. The aim of the project was to develop two electronic systems. One of them reads different parameters (temperature, humidity, eCO2) of the room air and sends a command to the second electronic unit via Bluetooth Low Energy when adjustable limit values are exceeded. This then opens or closes a tilt window using a purchased window motor. An app is also being developed to modernise and simplify the setup and control of the automatic window system.

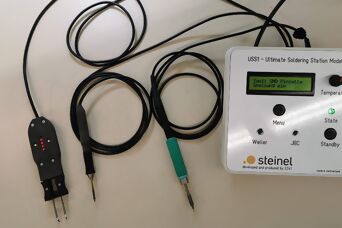

Universal soldering station

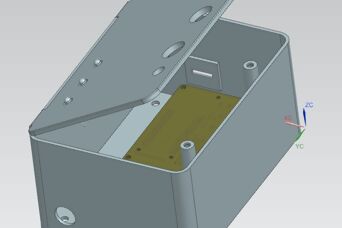

Simon and Selim have developed a universal soldering station by analysing various commercially available soldering stations and carrying out measurements. They developed and programmed their own circuit to control soldering tips and a desoldering bar. After testing and improving several prototypes, they built the final version in a plastic housing with buttons, potentiometer and display. The soldering station is now being used in vocational training. In an additional vocational training project, Michael has designed desoldering tweezers that can be operated together with the soldering station.

Desoldering tweezers

Michael has developed desoldering tweezers to complement the soldering station, which can be used independently or in combination. The housing was designed by Jonas and a 3D printer was used to create a compact, comfortable and stable handle. The desoldering tweezers are operated with just two buttons and their status can be read off using five LEDs. There is a motion sensor in the handle that automatically switches to standby mode if the tweezers lie still on the table for an extended period of time. The biggest challenge of the project was to integrate all the electronics into the handle of the tweezers, but the end result is very handy and easy to use.

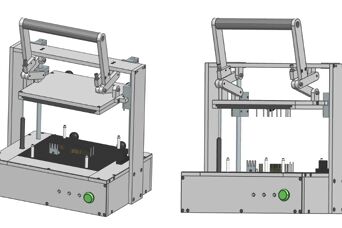

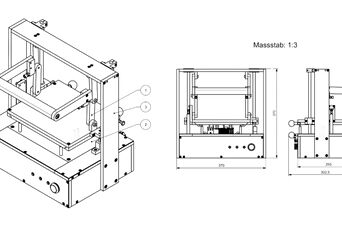

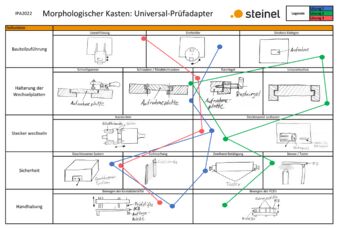

Universal test adapter for printed circuit boards

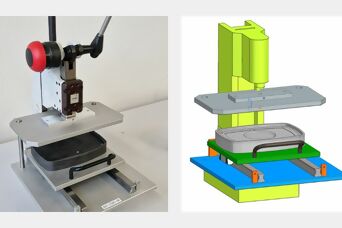

As individual practical work (IPA), Daniel was given the task of constructing a universal test adapter for printed circuit boards. He planned the project according to the IPERKA method (inform, plan, decide, realise, control, evaluate). Using a mind map and morphological box, he sketched three variants and then determined the best one. The toggle press turned out to be the best variant. He designed this and calculated the required press force and lever length. Of course, this also includes drawing up the production plans and documenting them neatly. Previously, a fixture had to be built for each blank. Thanks to the universal test fixture, it is now sufficient to manufacture only the fixtures for the PCB. Changing over to other PCBs is also very quick and uncomplicated.

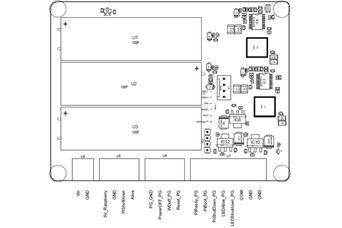

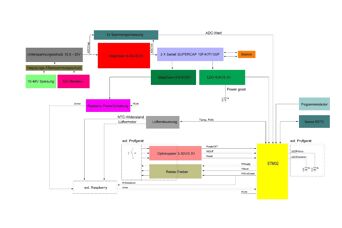

Raspberry Pi Control

As individual productive work (in the ordinary qualification procedure), Simon developed monitoring and energy buffer electronics for test systems of STEINEL Solutions AG. A Raspberry PI (single-board Linux PC) is installed in some of STEINEL Solutions AG's test systems and performs certain control, monitoring and test functions when modules are tested. To ensure that the operating system is shut down in a controlled manner when this Linux computer is disconnected from the power supply, the supply voltage must be buffered, a mains failure detected and this status continuously communicated to the computer. Simon successfully designed and developed such monitoring electronics.

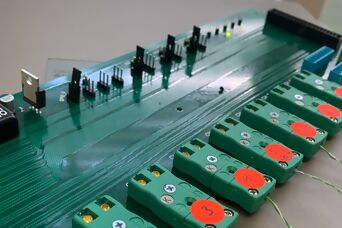

Multi-channel temperature measuring device

In the first step, Felix developed a temperature measurement card for a measurement system for his IPW (individual practical work) so that one can collect data from endurance tests of different devices. The project is part of an expandable measuring system. More cards can be developed to additionally measure e.g. voltages or currents. The basis of this system is the control element called Raspberry Pi (single board computer). Felix has written software for this with the Python programming language, which runs on the Raspberry Pi.

Compressor control

The compressor system at STEINEL Solutions AG has a timer that is adapted to the production operating hours. Previously, the room was accessible so that the compressor could be switched on outside production hours if necessary. Since the room is now locked, our apprentice Simon has developed an electronic system that allows the compressor to be switched on for four hours by means of an SMS.

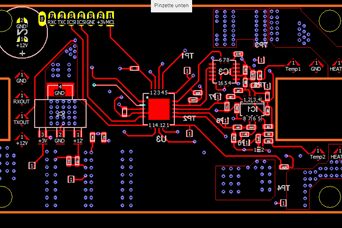

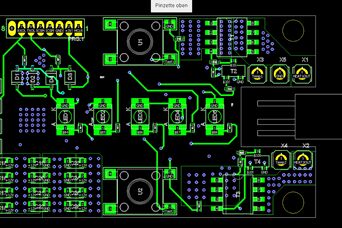

Soldering station

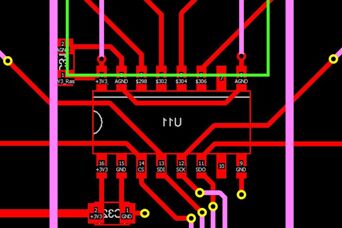

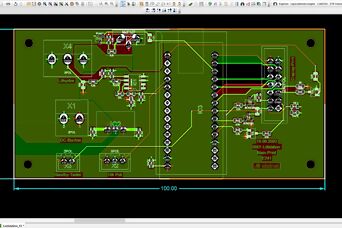

Simon and Selim, two of our apprentices, regularly worked on the project «soldering station», in which they were able to design one themselves. They used a commercial soldering station as a reference, on which they repeatedly took measurements and recorded them in order to understand the exact functions and rules of a soldering station. From the knowledge gained from this, they developed their own circuit to control the soldering iron and programmed an Arduino Nano (microprocessor platform) so that the temperature set on a potentiometer is shown on the display and correctly readjusted on the soldering iron. The circuit was tested extensively and then implemented in the layout programme in such a way that it could then be installed in a housing with the display and the potentiometer.

What our apprentices say about their training at STEINEL Solutions:

This is what our vocational trainers have to say about training at STEINEL Solutions:

Andreas Zehnder, Vocational Instructor Electronics Engineers

«It is a lot of fun to accompany young people for four years and to follow their development and progress. The feeling of being able to realise something with them is incredible. Be it the trainees' own ideas or internal company projects. I enjoy passing on my knowledge and it makes my job as a developer even more varied. I also really appreciate the fact that we train people for the job market and prepare them for their future everyday life. Because as a company of our size, you can't just always look for and hire qualified people, but you should also make a contribution yourself so that these young people come onto the market in the first place.»

André Bisig, Vocational Instructor Design Engineers

«On one hand, I find it great to pass on my own experience to young motivated people. I really enjoy working with apprentices on various projects and it's always an exciting challenge.

On the other hand, it benefits the image and name recognition of STEINEL Solutions. Training the next generation is not only sustainable, it also secures the future of the company.»

Are you interested in an apprenticeship at STEINEL Solutions?

We look forward to hearing from you!

Send us an e-mail.